Measurement Services

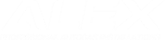

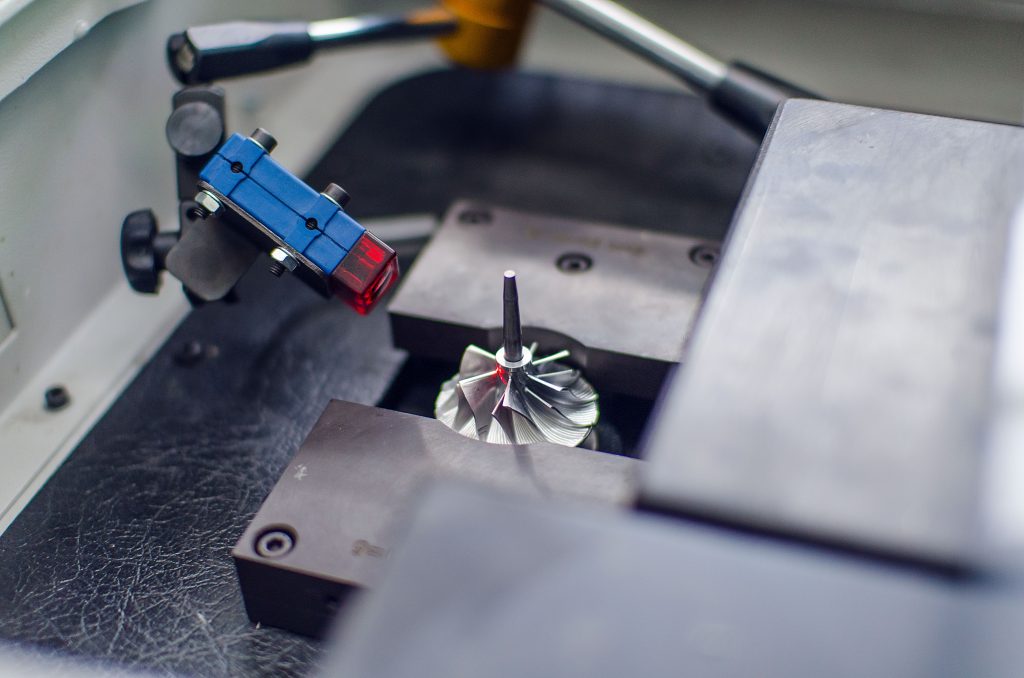

Control and Measurement Chamber

A modern, computerized measuring chamber, equipped with professional measuring devices, allows for accurate and quick control of the details.

Measuring machines:

-

-

- Coordinate measuring machine Mitutoyo CRYSTA-Apex S7106 (with scanning and contact probe)

- Keyence IM-6225 optical measuring machine

- Mahr MarSurf CD 120 contourograph

- Measuring machine for checking tolerances in shape and position Mahr MarForm MMQ 150

- Spectroport PXC01 spark spectrometer

- Rockwell hardness tester INNOVATEST Fenix 200AR

- Mitutoyo SJ-210 roughness gauge

- Tesa Hite 700 altimeter.

-

In addition, manual measuring equipment: micrometers, 2 and 3-point inside gauges, calipers, gauge blocks, measuring rollers, gauges for threads and holes, dial gauges and others. All measuring devices have current approvals and calibration certificates.

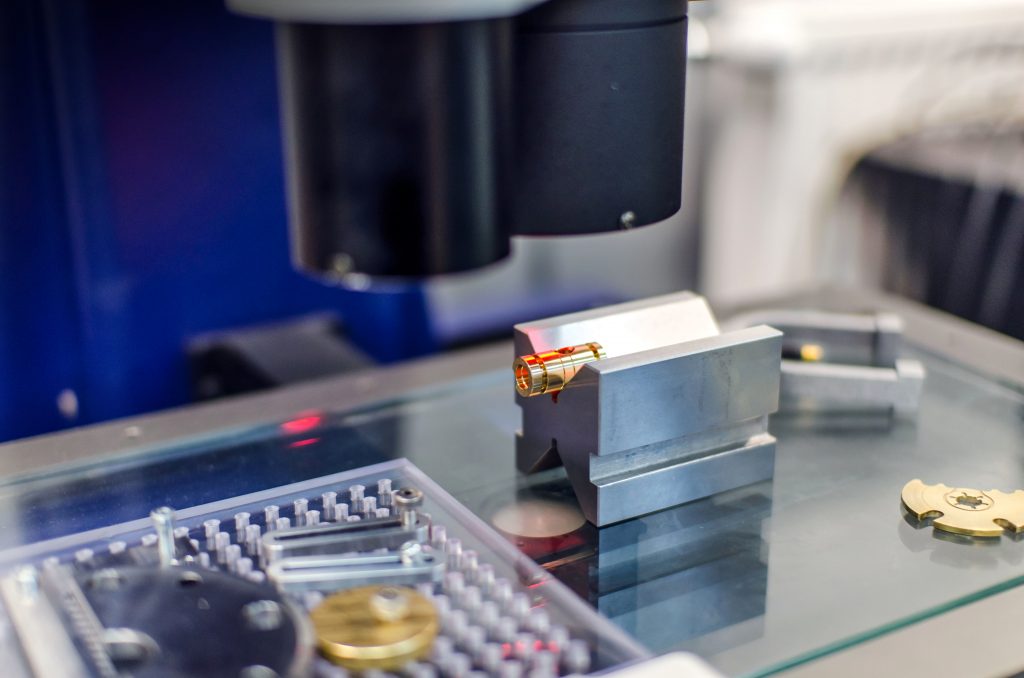

Coordinate measuring machine

Mitutoyo CRYSTA-Apex S7106

with scanning and contact probe.

Advanced CMM that allows very accurate measurements at high speed.

Specification:

- Measuring range: 700 x 1000 x 600 mm

- Poll: Renishaw SP25M

- Accuracy: 1.7 + 3L / 1000μm (at 18-22°C)

- Workpiece weight: up to 1000 kg

- Travel speed: 519 mm/s (3-axis)

Spectroport PXC01 spectrometer

A measuring machine designed to test the elemental composition of metal alloys.

Measurements of the alloy composition can be used, for controlling the supply of material or determining the alloy from which the detail is made (reverse engineering). Unlike manual XRFs, it accurately analyzes elements such as C, P, S, B, Li, Be, Ca, Si, Mg and Al, even at low and critical levels. Thanks to battery power, it can work in the field.

Our spectrometer allows you to test iron alloys (ordinary and alloy steels, stainless, acid-resistant steels, cast iron), copper alloys (brass and bronze) and aluminum. The analysis takes only a dozen or so seconds and only minimally damages the tested detail (burn trace with a diameter of approx. 5 mm). As a test result, we obtain the percentage of elements in the alloy and matched material grades in accordance with this composition.

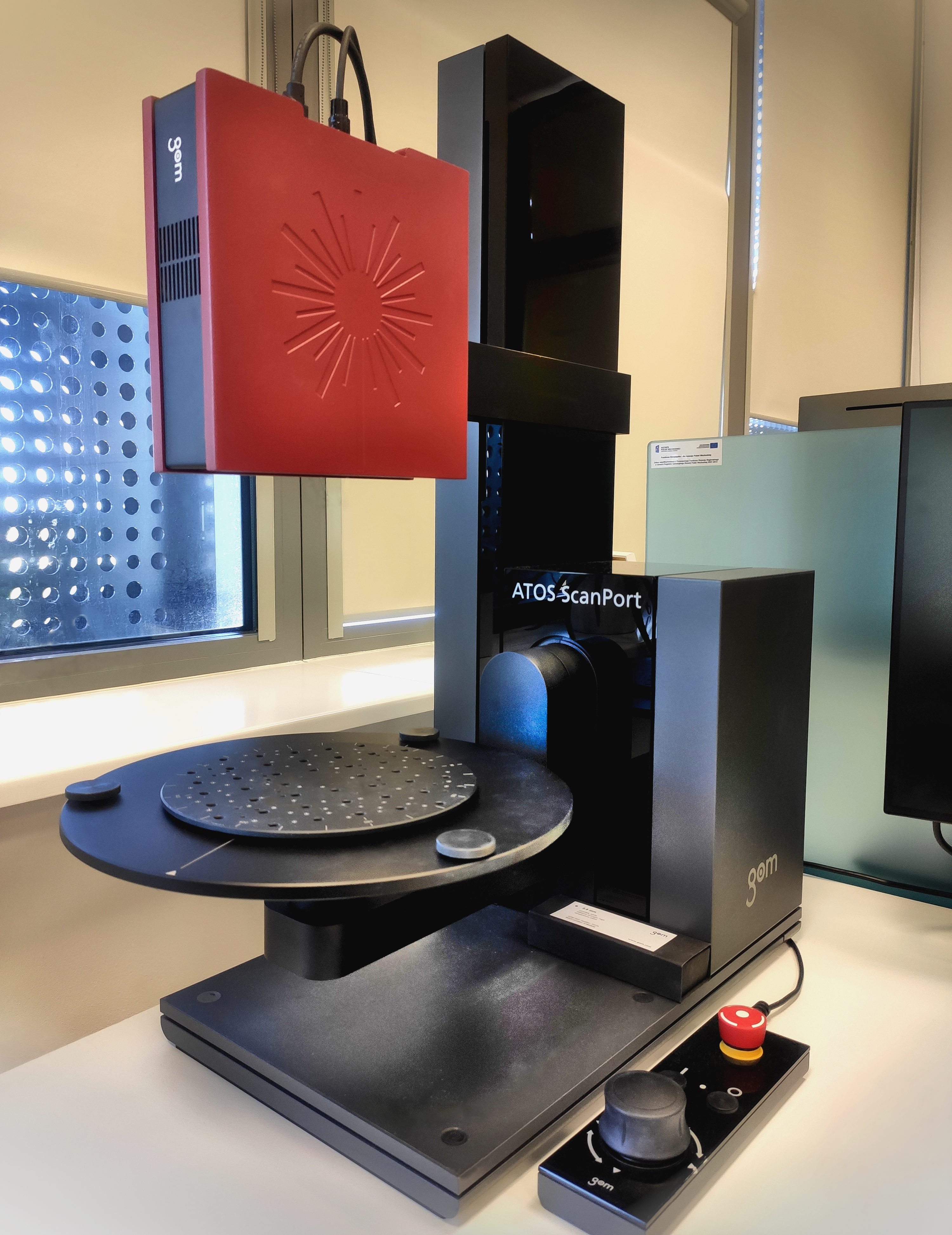

3D Scanning

Optical 3D scanner Atos Core 135 with Scan Port base

Advanced measurement tool for reverse engineering and inspection of details of complex shape.

Our optical scanner is designed for 3D mapping of the elements delivered to us. First, its digital model is developed, on the basis of which we can make a detail.

We use scanning in processes such as:

- reverse engineering

- simulations and prototypes

- quality control and wear tests

- design

- non-contact research

- dimensioning – measurements of geometry, volume and surface area

- digitization and simulations

- and other.

Contact us:

![]() ALEX Sp. z o.o.

ALEX Sp. z o.o.

Construction and Technology Department

ul. Przędzalniana 8a, 15-688 Białystok, POLAND